GreenHomeNYC volunteers got an exciting opportunity to learn about energy audits by participating in a home energy audit demonstration by members of Power Concepts’ Energy Division. The group preformed an ASHRAE level-one audit on a four-story Brownstone in Park Slope. While GreenHomeNYC does NOT offer energy audits, this was an excellent opportunity for our volunteer conservationists to join in on a thorough audit and better understand cost-effective energy saving measures firsthand. Here’s what they learned:

A typical ASHRAE Level 1 energy audit includes a visual inspection of the boiler room, the apartments, and the building envelope. An

audit identifies where why and a building is losing energy, and how to address the problems to increase resident comfort and save money. From the one day site inspection, Power Concepts prepared a brief report for the building’s residents detailing various measures the building could take to improve comfort and reduce energy costs. Read more about the building and our audit after the jump!

The Building

The Building

The building audited was a four-story walk up in Park Slope. It was built in 1894, has four units with 2 to 3 bedrooms and 1 to 2 bathrooms each, and a basement. Each floor is 1,207 sq. ft., for a total area of 6,035 sq ft, including the basement.

Space heat for the building is provided by a

1-pipe steam system with

#2 oil as the primary heating fuel. Two gas-fired water heaters provide domestic hot water (DHW) for the building. As we found out from the residents, these were added about ten years ago to relieve the boiler of DHW duties in the summer months and are now used year-round for this purpose.

Prior to the visit a fuel use analysis was conducted to estimate the building’s annual heating efficiency based on the amount of heating oil used in relation to the average outdoor temperature throughout the year. This analysis provides a useful snapshot of the overall efficiency of the building’s heating system and allows the auditor to get a sense of how the building is preforming before the visit.

Initial Complaints

Prior to the visit, residents described a number of comfort-related issues to the auditors. Among them were:

- Hot Water: Residents on the top floors were unable to get adequate hot water within a reasonable amount of time.

- Heating: Some residents were overheated while others have been too cold – a common problem in NYC. The thermostat for the entire building is located in the 2nd floor apartment – the ramifications of this are discussed in our Recommendations.

The Energy Audit

- The audit considered a number of building components in each unit:

- Light fixture count and types

- Window count and sizes

- Radiator inventory and settings

- Water fixture efficiency, flow rate, and hot water temperature

- Infrared photos of key areas to determine the infiltration of cold air, the performance of radiators, and other thermal issues

In the boiler room we measured:

- Solid State Efficiency (SSE) test to measure the boiler’s heating efficiency

- Piping configurations for heat and hot water service

- Settings on heat timers which control the amount of heat delivered to the building based on the outdoor temperature. Appropriate settings have a major impact on the building being under- or over heated, and thus, on energy usage overall

Finally, we measured to footprint of the building to determine its square footage.

Recommendations

About half of a home’s energy use is due to heating and cooling – as such our eight recommendations primarily relate to these processes:

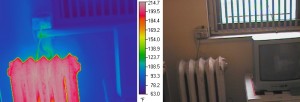

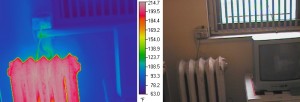

1. Insulate Steam and Hot Water Pipes

It is important to insulate all hot pipes to reduce wasted energy. Insulating pipes ensures that heat gets where it is needed – radiators and faucets. Conservation and efficiency start with being able to control heat. We measured roughly 100 ft. of uninsulated piping throughout the building, not including the boiler room which also lacked any pipe insulation. The image below shows an uninsulated steam riser in an apartment, leaching uncontrolled heat into an apartment:

2. Install Thermostatic Radiator Valves (TRVs) on all Radiators and Replace Existing Air Vents

TRVs

2. Install Thermostatic Radiator Valves (TRVs) on all Radiators and Replace Existing Air Vents

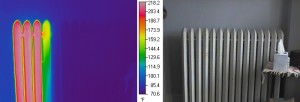

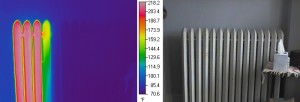

TRVs allows users to control room temperature by regulating the flow of steam to the radiator – just like a thermostat. When the temperature in the room reaches the specified set point, the TRV will shut the radiator off, even if the thermostat on a floor far away continues to tell the boiler it is cold. Each degree the building is heated above 68°F increases the heating bill by about 3%. Since many NYC apartments are over 80°F, setting all the TRVs in a building to 72°F can save thousands of dollars. Below are pictures of a radiator without a TRV, then with a TRV:

3. Relocate Boiler Thermostat to the 4th Floor Apartment

The

boiler thermostat is located in the second floor apartment’s living room. This could cause the thermostat to be satisfied before full steam circulation is established. In a centrally controlled boiler plant, the thermostat controlling the boiler should be on the radiator furthest from the boiler. Since that is not the case in this building, the upper floors often lack heat because the thermostat is satisfied on the 2nd floor, so the boiler shuts off. If the upper floors need more heat and the thermostat is turned up on the 2nd floor, then the lower floors may get overheated. We recommend moving the thermostat from the 2nd floor apartment to the 4th floor to decentralize temperature control as much as possible.

The NYC Housing Maintenance Code states that indoor temperature must be at least 68°F between 6:00 AM to 10:00 PM whenever the outdoor temperature falls below 55°F during the heating season (October 1 to May 31), and allows the indoor temperature to drop to 55°F from 10:00 PM to 6:00 AM whenever the outdoor temperature is below 40°F.

There is an opportunity for fuel savings by turning the temperature down in the evenings when most residents are asleep – this is called a night setback. The thermostat in this building is capable of achieving this night setback, but the day and night settings were set to essentially the same temperature. We recommend using the night setback feature on the thermostat to lower the temperature approximately 5 degrees cooler than the daytime setting.

4. Install Faucet Aerators and Engineered Showerheads at all Water Outlets

The water temperatures on some fixtures on the third and fourth floors were well below what they should be – ideally, domestic hot water (DHW) temperatures should be around 120°F. Hotter temperatures could risk scalding occupants while lower temperatures pose the risk of

Legionnaires’ Disease. We recommend installing efficient aerators and engineered showerheads on all water outlets to conserve water.

We also observed several apartments with inefficient top-loading washing machines. We recommend that residents with top-loading washing machines replacing their machines with

Energy Star front-loading machines on an as-fail basis to save water and electricity.

5. Caulk and Weatherstrip Windows and Doors

Though it was mild during our visit, we did observe some cold air infiltration around windows and electrical outlets. On colder days, these issues are likely more extreme.

We recommend caulking and weatherstripping around all windows, doors and outlets. This is particularly important to do at the top and bottom of the building to prevent

stack effect – cold air being sucked in from lower floors and hot air pushed out at upper floors.

6. Replace Incandescent Lights with Low-Wattage CFLs

The majority of lighting in apartments was from incandescent bulbs.

Compact fluorescent bulbs are more cost effective than ever and are available in a wide range of shades. Any bulb rated between 2700 – 3000K with a color rendering index (CRI) of 85 or higher will provide light similar in color to that of incandescent bulbs (“Warm White”), but will use roughly a third of the electricity. We also observed several halogen-type MR-16 bulbs in some of the kitchens, which can be replaced with new

LED MR-16s, which use one tenth as much energy.

We recommend replacing the existing incandescent and halogen bulbs with more efficient models – this should be done over an extended period of time as the existing bulbs burn out, since it will not be cost effective to replace bulbs with low usage.

7. Burner Efficiency

We preformed a steady state efficiency (SSE) test on the boiler. We found the SSE to be 83%, which translates to an annual fuel utilization efficiency (AFUE) of about 73%. This was actually very good for this particular boiler – likely the maximum efficiency.

We recommend that the building maintains the boiler at this efficiency by

scheduling annual

burner tune-ups with their boiler mechanic. We also recommend the installation of a stack

thermometer to periodically monitor the temperature of the boiler flue gas. By tracking the maximum temperature of the flue gas, one can monitor the efficiency and schedule maintenance as needed.

8. Domestic Hot Water (DHW) Supply

DHW is supplied by two gas-fired atmospheric boilers in the basement. We believe that the combined output of these units should be enough to satisfy the demand for the building, but residents have experienced low temperatures at the upper floors, and a long waiting period for it to heat up. This is particularly surprising since the temperature setting on the tanks is set to ~140°F, which is hotter than necessary. A few approaches could solve this problem:

- The lack of pipe insulation could account for significant heat loss.

- Neither of the water heaters fired once while we were in the basement – nearly an hour’s time. There may be a problem with the aquastats on the heaters.

- The boiler still seems to still be connected to the DHW system. We observed that the hot water valve from the boiler’s coil was about half open.

- Install strap-on thermometers downstream of the mixing valve and on the pipes coming out of each water heater. This allows for the measurement of the temperature of the water being sent from those devices against what the aquastats (hot water heater temperature controls) are set to. This could help determine that something is wrong with one, or both, of the units.

- If pipe insulation does not solve the problem, we recommend a further study be done of the DHW system to determine the cause of the low temperatures on the upper floors. It may be that the units were undersized, or that the half open valve from the boiler coils is causing the water heater’s output to unnecessarily run through the mixing valve, thereby cooling it further.

- Finally, use the boiler for DHW during the winter months as it is operating at a higher efficiency during that time than the water heaters combined, and the water heaters only during the summer months.

More on Energy Audits

Energy audits can range from a simple walk through like this, to extensive, detailed analyses conducted by accredited engineers, such as

ASHRAE Level II and Level III audits that take into operations and maintenance procedures, a high level of monitoring and data collection, and detailed measures of implementation costs and payback.

New York City’s

Local Law 87 now requires ALL buildings over 50,000 sq ft to undergo an ASHRAE Level II audit every 10 years starting in 2013. The energy audit is on its way to becoming a fundamental part of the regulations on New York City’s built environment. This is a welcome development – when seeing the range of issues identified in a simple audit of a small building, it is easy to extrapolate the findings on a city-wide, more detailed scale, and recognize the energy savings that could result.

We encourage you to ask any questions about our findings, comment on any aspects you feel were not addressed, or simply convey any other thoughts you have on this process. Every building is different and we’d love to hear about your experiences or recommendations!

The Building

The building audited was a four-story walk up in Park Slope. It was built in 1894, has four units with 2 to 3 bedrooms and 1 to 2 bathrooms each, and a basement. Each floor is 1,207 sq. ft., for a total area of 6,035 sq ft, including the basement.

Space heat for the building is provided by a 1-pipe steam system with #2 oil as the primary heating fuel. Two gas-fired water heaters provide domestic hot water (DHW) for the building. As we found out from the residents, these were added about ten years ago to relieve the boiler of DHW duties in the summer months and are now used year-round for this purpose.

Prior to the visit a fuel use analysis was conducted to estimate the building’s annual heating efficiency based on the amount of heating oil used in relation to the average outdoor temperature throughout the year. This analysis provides a useful snapshot of the overall efficiency of the building’s heating system and allows the auditor to get a sense of how the building is preforming before the visit.

Initial Complaints

Prior to the visit, residents described a number of comfort-related issues to the auditors. Among them were:

The Building

The building audited was a four-story walk up in Park Slope. It was built in 1894, has four units with 2 to 3 bedrooms and 1 to 2 bathrooms each, and a basement. Each floor is 1,207 sq. ft., for a total area of 6,035 sq ft, including the basement.

Space heat for the building is provided by a 1-pipe steam system with #2 oil as the primary heating fuel. Two gas-fired water heaters provide domestic hot water (DHW) for the building. As we found out from the residents, these were added about ten years ago to relieve the boiler of DHW duties in the summer months and are now used year-round for this purpose.

Prior to the visit a fuel use analysis was conducted to estimate the building’s annual heating efficiency based on the amount of heating oil used in relation to the average outdoor temperature throughout the year. This analysis provides a useful snapshot of the overall efficiency of the building’s heating system and allows the auditor to get a sense of how the building is preforming before the visit.

Initial Complaints

Prior to the visit, residents described a number of comfort-related issues to the auditors. Among them were:

2. Install Thermostatic Radiator Valves (TRVs) on all Radiators and Replace Existing Air Vents

TRVs allows users to control room temperature by regulating the flow of steam to the radiator – just like a thermostat. When the temperature in the room reaches the specified set point, the TRV will shut the radiator off, even if the thermostat on a floor far away continues to tell the boiler it is cold. Each degree the building is heated above 68°F increases the heating bill by about 3%. Since many NYC apartments are over 80°F, setting all the TRVs in a building to 72°F can save thousands of dollars. Below are pictures of a radiator without a TRV, then with a TRV:

3. Relocate Boiler Thermostat to the 4th Floor Apartment

The boiler thermostat is located in the second floor apartment’s living room. This could cause the thermostat to be satisfied before full steam circulation is established. In a centrally controlled boiler plant, the thermostat controlling the boiler should be on the radiator furthest from the boiler. Since that is not the case in this building, the upper floors often lack heat because the thermostat is satisfied on the 2nd floor, so the boiler shuts off. If the upper floors need more heat and the thermostat is turned up on the 2nd floor, then the lower floors may get overheated. We recommend moving the thermostat from the 2nd floor apartment to the 4th floor to decentralize temperature control as much as possible.

The NYC Housing Maintenance Code states that indoor temperature must be at least 68°F between 6:00 AM to 10:00 PM whenever the outdoor temperature falls below 55°F during the heating season (October 1 to May 31), and allows the indoor temperature to drop to 55°F from 10:00 PM to 6:00 AM whenever the outdoor temperature is below 40°F.

There is an opportunity for fuel savings by turning the temperature down in the evenings when most residents are asleep – this is called a night setback. The thermostat in this building is capable of achieving this night setback, but the day and night settings were set to essentially the same temperature. We recommend using the night setback feature on the thermostat to lower the temperature approximately 5 degrees cooler than the daytime setting.

4. Install Faucet Aerators and Engineered Showerheads at all Water Outlets

The water temperatures on some fixtures on the third and fourth floors were well below what they should be – ideally, domestic hot water (DHW) temperatures should be around 120°F. Hotter temperatures could risk scalding occupants while lower temperatures pose the risk of Legionnaires’ Disease. We recommend installing efficient aerators and engineered showerheads on all water outlets to conserve water.

We also observed several apartments with inefficient top-loading washing machines. We recommend that residents with top-loading washing machines replacing their machines with Energy Star front-loading machines on an as-fail basis to save water and electricity.

5. Caulk and Weatherstrip Windows and Doors

Though it was mild during our visit, we did observe some cold air infiltration around windows and electrical outlets. On colder days, these issues are likely more extreme.

We recommend caulking and weatherstripping around all windows, doors and outlets. This is particularly important to do at the top and bottom of the building to prevent stack effect – cold air being sucked in from lower floors and hot air pushed out at upper floors.

6. Replace Incandescent Lights with Low-Wattage CFLs

The majority of lighting in apartments was from incandescent bulbs. Compact fluorescent bulbs are more cost effective than ever and are available in a wide range of shades. Any bulb rated between 2700 – 3000K with a color rendering index (CRI) of 85 or higher will provide light similar in color to that of incandescent bulbs (“Warm White”), but will use roughly a third of the electricity. We also observed several halogen-type MR-16 bulbs in some of the kitchens, which can be replaced with new LED MR-16s, which use one tenth as much energy.

We recommend replacing the existing incandescent and halogen bulbs with more efficient models – this should be done over an extended period of time as the existing bulbs burn out, since it will not be cost effective to replace bulbs with low usage.

7. Burner Efficiency

We preformed a steady state efficiency (SSE) test on the boiler. We found the SSE to be 83%, which translates to an annual fuel utilization efficiency (AFUE) of about 73%. This was actually very good for this particular boiler – likely the maximum efficiency.

We recommend that the building maintains the boiler at this efficiency by scheduling annual

burner tune-ups with their boiler mechanic. We also recommend the installation of a stack

thermometer to periodically monitor the temperature of the boiler flue gas. By tracking the maximum temperature of the flue gas, one can monitor the efficiency and schedule maintenance as needed.

8. Domestic Hot Water (DHW) Supply

DHW is supplied by two gas-fired atmospheric boilers in the basement. We believe that the combined output of these units should be enough to satisfy the demand for the building, but residents have experienced low temperatures at the upper floors, and a long waiting period for it to heat up. This is particularly surprising since the temperature setting on the tanks is set to ~140°F, which is hotter than necessary. A few approaches could solve this problem:

2. Install Thermostatic Radiator Valves (TRVs) on all Radiators and Replace Existing Air Vents

TRVs allows users to control room temperature by regulating the flow of steam to the radiator – just like a thermostat. When the temperature in the room reaches the specified set point, the TRV will shut the radiator off, even if the thermostat on a floor far away continues to tell the boiler it is cold. Each degree the building is heated above 68°F increases the heating bill by about 3%. Since many NYC apartments are over 80°F, setting all the TRVs in a building to 72°F can save thousands of dollars. Below are pictures of a radiator without a TRV, then with a TRV:

3. Relocate Boiler Thermostat to the 4th Floor Apartment

The boiler thermostat is located in the second floor apartment’s living room. This could cause the thermostat to be satisfied before full steam circulation is established. In a centrally controlled boiler plant, the thermostat controlling the boiler should be on the radiator furthest from the boiler. Since that is not the case in this building, the upper floors often lack heat because the thermostat is satisfied on the 2nd floor, so the boiler shuts off. If the upper floors need more heat and the thermostat is turned up on the 2nd floor, then the lower floors may get overheated. We recommend moving the thermostat from the 2nd floor apartment to the 4th floor to decentralize temperature control as much as possible.

The NYC Housing Maintenance Code states that indoor temperature must be at least 68°F between 6:00 AM to 10:00 PM whenever the outdoor temperature falls below 55°F during the heating season (October 1 to May 31), and allows the indoor temperature to drop to 55°F from 10:00 PM to 6:00 AM whenever the outdoor temperature is below 40°F.

There is an opportunity for fuel savings by turning the temperature down in the evenings when most residents are asleep – this is called a night setback. The thermostat in this building is capable of achieving this night setback, but the day and night settings were set to essentially the same temperature. We recommend using the night setback feature on the thermostat to lower the temperature approximately 5 degrees cooler than the daytime setting.

4. Install Faucet Aerators and Engineered Showerheads at all Water Outlets

The water temperatures on some fixtures on the third and fourth floors were well below what they should be – ideally, domestic hot water (DHW) temperatures should be around 120°F. Hotter temperatures could risk scalding occupants while lower temperatures pose the risk of Legionnaires’ Disease. We recommend installing efficient aerators and engineered showerheads on all water outlets to conserve water.

We also observed several apartments with inefficient top-loading washing machines. We recommend that residents with top-loading washing machines replacing their machines with Energy Star front-loading machines on an as-fail basis to save water and electricity.

5. Caulk and Weatherstrip Windows and Doors

Though it was mild during our visit, we did observe some cold air infiltration around windows and electrical outlets. On colder days, these issues are likely more extreme.

We recommend caulking and weatherstripping around all windows, doors and outlets. This is particularly important to do at the top and bottom of the building to prevent stack effect – cold air being sucked in from lower floors and hot air pushed out at upper floors.

6. Replace Incandescent Lights with Low-Wattage CFLs

The majority of lighting in apartments was from incandescent bulbs. Compact fluorescent bulbs are more cost effective than ever and are available in a wide range of shades. Any bulb rated between 2700 – 3000K with a color rendering index (CRI) of 85 or higher will provide light similar in color to that of incandescent bulbs (“Warm White”), but will use roughly a third of the electricity. We also observed several halogen-type MR-16 bulbs in some of the kitchens, which can be replaced with new LED MR-16s, which use one tenth as much energy.

We recommend replacing the existing incandescent and halogen bulbs with more efficient models – this should be done over an extended period of time as the existing bulbs burn out, since it will not be cost effective to replace bulbs with low usage.

7. Burner Efficiency

We preformed a steady state efficiency (SSE) test on the boiler. We found the SSE to be 83%, which translates to an annual fuel utilization efficiency (AFUE) of about 73%. This was actually very good for this particular boiler – likely the maximum efficiency.

We recommend that the building maintains the boiler at this efficiency by scheduling annual

burner tune-ups with their boiler mechanic. We also recommend the installation of a stack

thermometer to periodically monitor the temperature of the boiler flue gas. By tracking the maximum temperature of the flue gas, one can monitor the efficiency and schedule maintenance as needed.

8. Domestic Hot Water (DHW) Supply

DHW is supplied by two gas-fired atmospheric boilers in the basement. We believe that the combined output of these units should be enough to satisfy the demand for the building, but residents have experienced low temperatures at the upper floors, and a long waiting period for it to heat up. This is particularly surprising since the temperature setting on the tanks is set to ~140°F, which is hotter than necessary. A few approaches could solve this problem:

Leave a Reply

You must be logged in to post a comment.